Pulsed high-current arc (HCA) with plasma filter

Together with Arc Precision GmbH, Aixcon developed a system for coating hard-disk surfaces with a carbon layer of 1.5 nm. The method is based on the evaporation of carbon in a vacuum. The energy is generated by means of pulsed high-current discharge (HCA sources). With a magnetic arc, the plasma is filtered and creates very thin, homogeneous carbon layers on the hard disk surface, thus reducing the distance of the read-write heads. This results in a much larger storage capacity with the same disk surface.

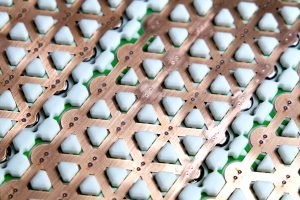

HCA technology (PVD coating)

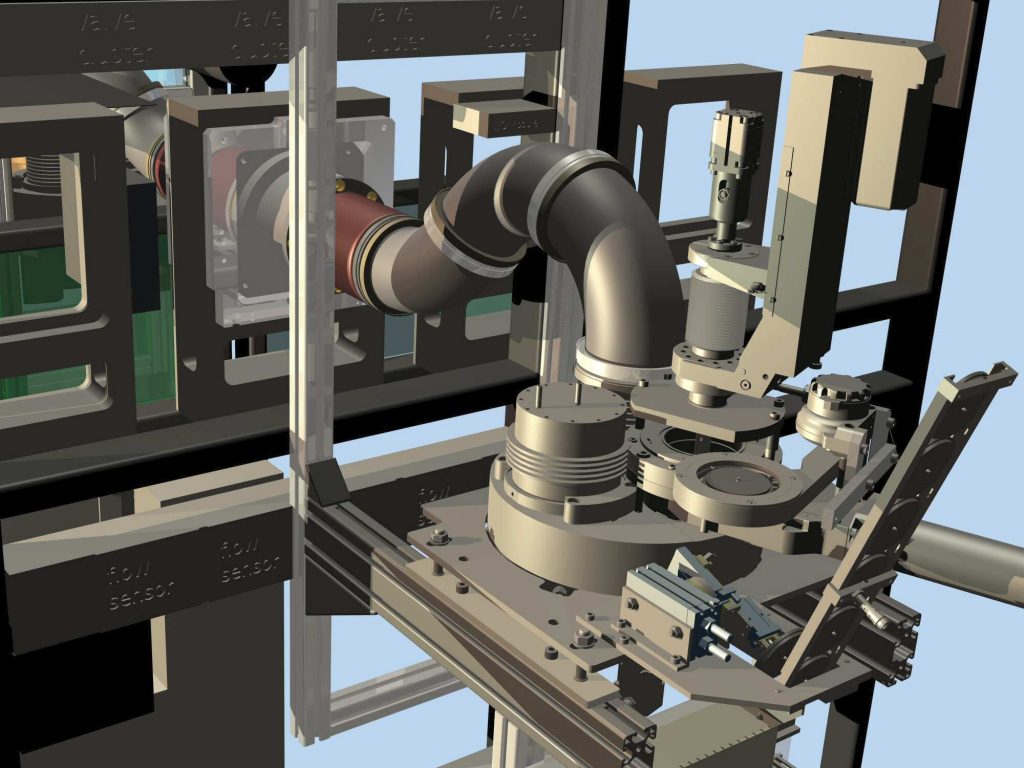

The applied material is deposited from a carbon target. A target is usually no longer usable after approx. 30 minutes and is automatically replaced during the running process. The target change is also carried out within the cycle time of the production line. When changing the carbon target, no deterioration of the vacuum should occur.

The cycle time of the production plant is in the seconds range. The coating time itself is under 1 second.

The vacuum arc is a rather simple coating method. Unfortunately, liquid drops of the target material deposit as so-called droplets, and the only possible way to avoid these droplets is to filter them out. While it is possible to filter the droplets in strong magnetic fields, it also causes extensive damage to the plasma, which greatly hinders its industrial use.

With the technology developed by Arc Precision and IWS and implemented by Aixcon, the process can now be used in industrial environments.

Aixcon offers the following systems:

- HCA pulse current source (5000A, 50kW)

- Contactless ignition (process and formation of the target)

- Power sources for filter sheets (1000A, 20V)

- Total control for engines (target changer) and valves (4 motors, 30 valves)

- Software for control, operation, and customer interface

- Maintenance and diagnostic access via internet connection