Hot stretcher & warm bending

Aixcon provides power sources for heat treatment. In a standard heat treatment, a material with an Aixcon current source is heated either directly using resistance or conductivity, or indirectly using radiation according to a given temperature profile. Once the target temperature is reached, the material (titanium, steel, aluminum, alloys, etc.) can be formed, hardened, and treated.

aixcon PowerSystems has developed a specially automated system for heat treatments, which is precisely controlled within 0.1 percent.

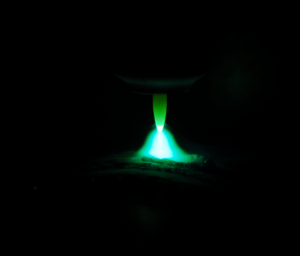

Hot stretching of titanium profiles

Titanium is the preferred material for load-bearing parts in the aerospace industry. At room temperature, titanium can only be formed using large forces. This method, however, carries the additional risk of damaging the crystalline structures of the titanium. For forming titanium, therefore, temperatures of about 700 ° C are ideally preferred. “Hot-stretching” uses the high electrical resistance of titanium to heat the workpiece with current, and then forms the workpiece with the stretcher. After extrusion, the titanium shapes must then be straightened. Aixcon has designed and built several plants with up to 30,000 ampere current (900 kW electrical power) in stretchers with up to 500 tons of cylinders.