Aixcon offers DC and AC power sources as well as microwave generators for a variety of coating processes. Aixcon in particular also supports processes that place high demands on the power supply, such as those with high pulse rates or special pulse shapes.

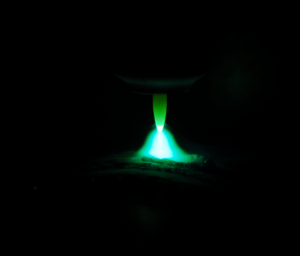

Microwave Coating

Microwaves (915 MHz / 2.45 GHz / 5.8 GHz) are a good source for plasma excitation. Microwaves can achieve higher plasma densities than RF or DC excitation. Aixcon’s microwave generators are deployed in various plasma coating processes (e.g. PCVD – Plasma Chemical Vapour Deposition). This coating process facilitates the deposition of many different types of thin films.

aixcon’s microwave generators can also be used in pulsed power regime (up to 20 kHz). The pulsed power regime can reduce the thermal load on the substrate. This facilitates coating applications on materials that do not tolerate high thermal loads (e.g. polymers).

Possible applications:

- Wafers

- Semiconductors

- ICs (Integrated Circuits)

- Photovoltaic

- Glass

Electroplating

Electroplating is a coating process in which current is passed through an electrolytic bath and material is stripped from the anode (positive pole) and coated onto the cathode (negative pole).

The advantage of electroplating is that the metal layer is very homogeneous. The thickness of the metal coating increases depending on the current density and process duration,

Depending on the material, the deposited coatings can be very functional with properties such as high wear resistance.

Feel free to contact us for more information.

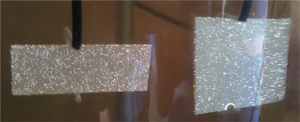

Plasma Electrolytic Oxidation (PEO)

Plasma Electrolytic Oxidation (PEO) is an electrochemical process to deposit ceramic-like layers on metals. The characteristic property of the PEO process is that the dielectric breakdown voltage is reached, which leads to discharges on the surface.

The PEO process is mainly used for optical, medical and aerospace applications.

Together with Innovent Jena e.V., Aixcon has developed a process that makes it possible to uniformly coat metals on both electrodes, regardless of their size and shape. This process were presented at the PSE 2016 in Garmisch-Partenkirchen. Click here for the project poster presentation.

Please contact us for further information.

Carbon coating (High Current Arc | HCA)

HCA coating (High Current Arc) is a process to deposit very thin and homogeneous carbon layers, and can be used in applications such as coating hard disks. The process was developed by ARC Precision GmbH. It is based on the evaporation of carbon in a vacuum. The energy is generated by pulsed high current discharges (HCA sources) which were developed by Aixcon.