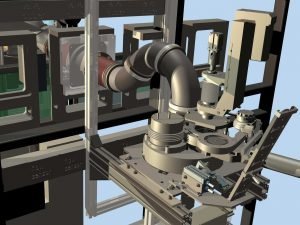

Welding system for copper cell connectors

Are you looking for a way to weld copper onto round cells to get even more power out of your battery packs? aixcon PowerSystems has developed a welding process that makes it possible to weld copper rails onto battery cells. Compared to the materials usually used as cell connectors (usually nickel-plated steel, nickel, etc.), the use of copper increases the electrical efficiency of the battery pack due to its increased conductivity. In addition, copper has excellent thermal conductivity and therefore serves as a heat sink.

Technical specifications:

System specifications

- Input power: 100 -127 / 200 -240 VAC (50/60 Hz)

- Gas flow: 5.1 cm/min (typical), 12.7 cm/min (max)

- Operating temperature: 10 -40°C

- Drives: Wear-free servo drives

- Rotary encoder: absolute value encoder

- Bearing: Circumferential linear bearings

Process specifications

- Welding process: tungsten inert gas welding

- Shielding gas: Argon (Ar)

- Output current 0-300A

- Ignition: Contactless

- Process rate: Up to 100 welds per minute

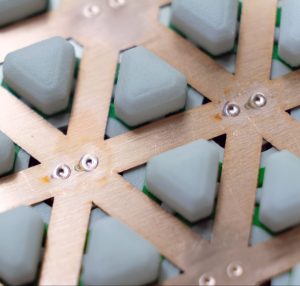

- Material connector: copper (low oxygen)

- Cell connector thickness: typically 0.2 or 0.3 mm (others on request)

- Battery cell type: cylindrical, e.g. 18650, 21700 or 26650 lithium batteries (others on request)

Highlights

- cell connector off

- copper

- High electrical and thermal conductivity

- TIG welding

- Contactless ignition

- Automated process

Sample applications

Powerful battery modules with high electrical conductivity are used in many industries.

- energy industry

- Stationary energy storage

- mobility

- Pedelec, e-bike, electric car, aerobatic plane

More about the numerous applications of our various welding systems.